whitepaper

Expand your knowledge!

Tools for Machine Deburring

Deburring: the art of surface finishing

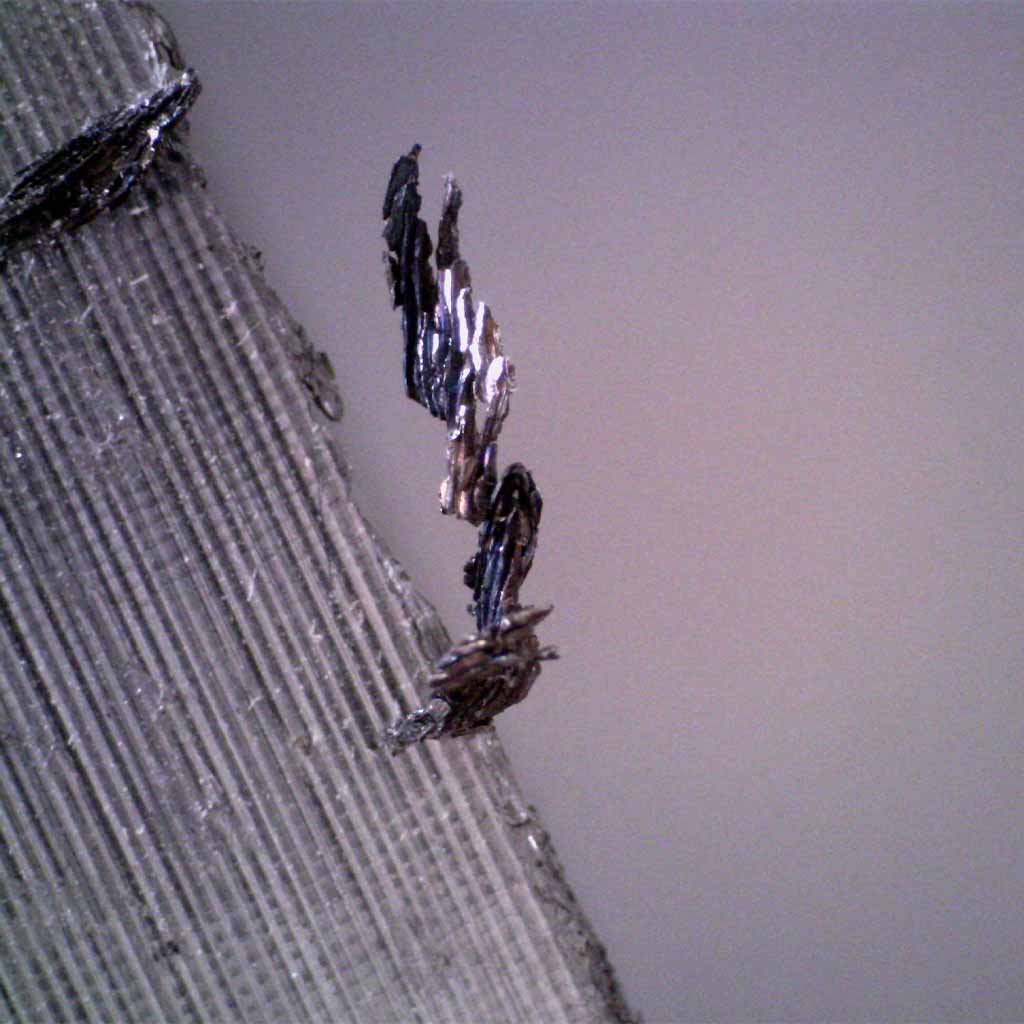

Deburring is a crucial step in the manufacturing industry that plays a significant role in the production of precise, high-quality parts. A burr can lead to injuries during handling and impair the function of the machines or, in the worst case, lead to failure. Deburring, therefore, plays an important role.

It should be said at the outset: burrs cannot be 100% avoided – even with the most modern manufacturing processes, this excess material occurs in the form of unwanted moulding on the component and is often visible as sharp edges on the contour of the workpiece. This can significantly impair the flawless functionality of a workpiece, as it can result in poor fitting accuracy, for example.

Find out more in our white paper

Different materials tend to form burrs in very different ways. The use of suitable deburring tools improves the properties and functionality of the product to be manufactured, reduces the dangers for people and machines, and can eliminate the need for manual reworking. Depending on the machining process, different tools can be used for deburring – from deburrers, indexable inserts and burrs to multifunctional tools.

In this white paper you will learn:

- How burrs are created and why deburring is important

- What the shape and size of the burr depend on

- Which tools are suitable for the various machining processes (CNC milling, turning, universal machining, manual deburring)

And even more!

Even more Know-how to go

One never stops learning, right? Learn more about “More performance when threading“, find out more about “Trochoidal milling: reduce costs, optimise processes” and master “Deep hole drilling“. In these white papers, we have summarised the most important information on these disciplines for you so that you are optimally prepared for the requirements.

The download is as simple as this:

- Fill in the form.

- Click on “send” – and you can already expand your knowledge!