We are certain that our machining solutions will help you make your machining more efficient. To live up to this claim, we continuously develop our products, services, and employees. Since 2017, we have been certified according to ISO 9001:2015 for development, sales, and logistics of precision tools.

Above all, striving for continuous improvement is part of our company philosophy. We believe that this is the only way to respond to our customers’ needs and to help them meet the ever-growing challenges they are facing now and in the future.

Constantly improving our company and our product range, we have now become one of the leading suppliers of cutting tools. Our products are used by major national and international companies and organisations from various industries including:

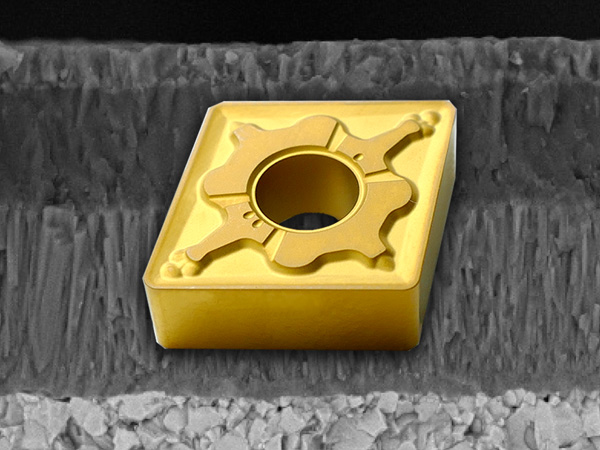

We provide high-quality precision tools made from high-performance and durable cutting materials. New milling technologies and the development of innovative strategies for machining advanced materials – such as titanium and nickel alloys and carbon composite materials – are core competencies of our day-to-day business.

Our tools are not only delivered straight to the end users for machining but are also sold by our retail customers. This is where we offer an important service: We support our distribution partners through tailored sales promotions and in the preparation of marketing materials to drive collaborative success. All solutions from TOOL FACTORY can also be ordered under “Private Label”.

You can count on us! It is important for us to deliver your orders as fast and easy as possible so that you can plan your production tasks to run properly and with no waiting times.

We always have over 22,000 different items available in our warehouse as well as in our online shop. Our spacious warehousing and modern stock management system allow us to respond to your requests in a fast and flexible way and ensure a high delivery performance of at least 93%. With a same-day-shipment of your orders we promise a delivery within the next working day.

Introducing the new Solid Carbide High-Performance End Mills of the 35401, 35402, and 35403 series to the market – premium quality, especially for mass production.

The first episode of our explainer videos for machining, SPAN-ART©, has been released.

Moreover, we have successfully entered a new market – Hello Eastern Europe!

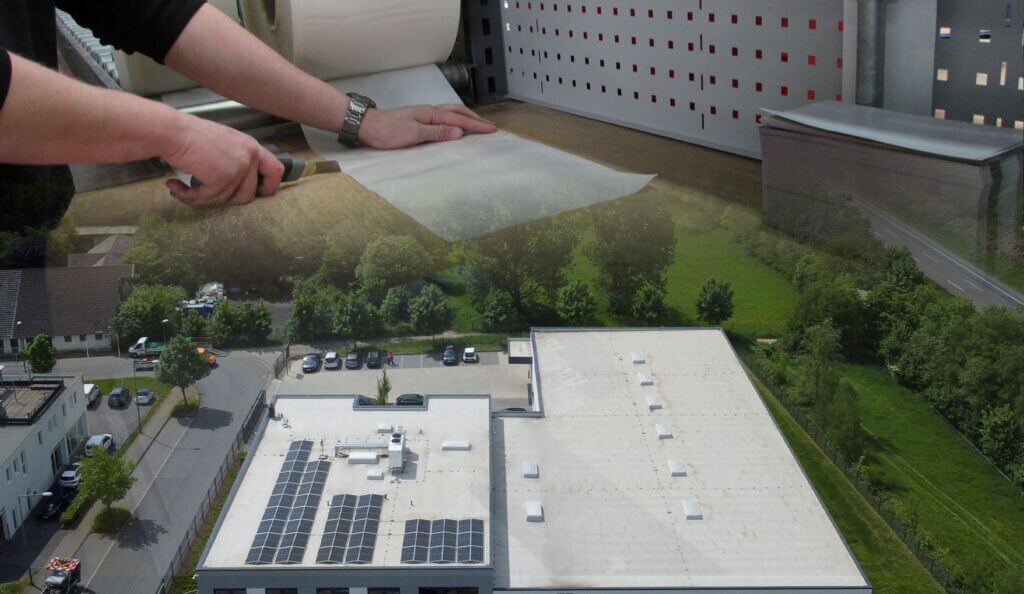

Move to our new building. We strive for growth, in employees as well as in customers and products.

Introduction of a web shop for customers where all mono tools, Flexible Line articles and machine taps can be ordered.

In a major fire, our warehouse was destroyed along with all of our stock. Fortunately, no one was injured.

TOOL FACTORY Cutting Tool Solutions GmbH is certified according to ISO 9001:2015 for development, sales, and logistics.

The field service is launched.

US Special Tools becomes TOOL FACTORY Cutting Tool Solutions GmbH. The number of in-house designs is growing steadily.

The company headquarters moves from Wipperfürth to Burscheid. The warehouse and office space expands from 500 sqm to 2,000 sqm.

Automation of a large number of processes and introduction of a warehouse management system.

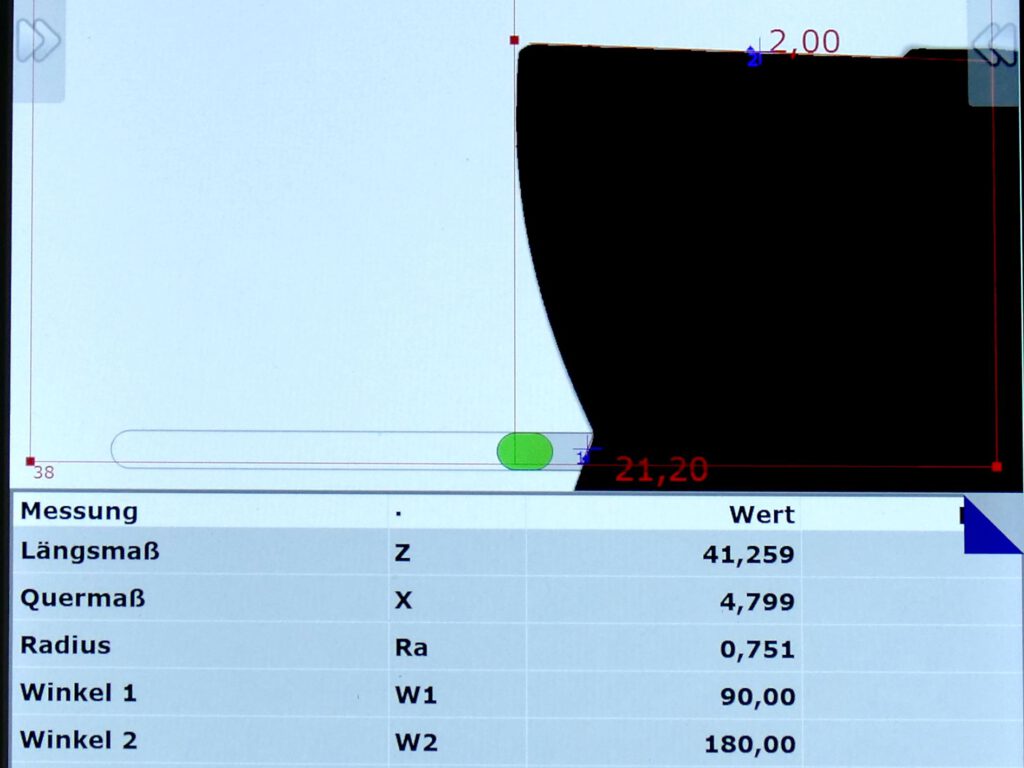

The product portfolio now includes indexable inserts for turning and milling applications.

Wolfgang Lambertz becomes Managing Director of US Special Tools.

Move to larger premises in the Hansestraße in Wipperfürth.

The range of products now includes drills.

The first laser is used for labeling the tools.

Move from Wipperfürth-Hämmern to Mühle 1 in Wipperfürth.

Introduction of a labelling machine

The team is getting bigger: US Special Tools grows to eight employees

Founded as US Special Tools, based in Wipperfürth-Hämmern, Germany. The portfolio includes milling tools (HSS/Solid Carbide tools/rotor/hole saws). Successive development of commercial agents and cooperation with associations

We set remarkably high ethical standards not only for ourselves but also for our suppliers’ practices. Therefore, we want to do our part to comply with the strict measures from the EU regulation and the Dodd-Frank Act to avoid the use of raw materials from risk areas. For this purpose, we have our suppliers confirm to us at regular intervals that they comply with and test these regulations.

Moreover, our products are regularly checked according to the REACH regulation – Registration, Evaluation and Authorization of Chemicals.

Sustainability and environmental awareness are a big concern, also at TOOL FACTORY. For this reason, we have replaced the bubble wrap with recycled packing paper, as well as the plastic adhesive tape with an environmentally friendly paper tape, so as to ensure the most ecological way of managing our packaging. And finally, we installed a photovoltaic system on the roof that not only meets the latest ecological standards but also will help ensure that our building is energy efficient. Regional projects on environmental protection are also a matter of concern to us. So, it became a priority for us to contribute to the city of Burscheid’s “Baumpflanz-Kampagne (Tree Planting Campaign)“.

It is important for us to support each other. As a result, we donated mouth and nose protection masks to, for instance, the “Luchtenberg-Richartz-Haus” centre for the elderly, the “Montanusschule” elementary school and the “Pastor-Löh-Schule” comprehensive school in Burscheid, when we realized that help was needed at these facilities.

Every year at Christmas time we donate the amount of money we otherwise would have spent on Christmas gifts to the Kinder- und Jugendhospiz Burgholz in Wuppertal, Germany. The Children’s Hospice Foundation Bergisches Land makes an important contribution to supporting families in giving their children and adolescents with mortal illnesses a fulfilling and dignified life until death. Through our donation, we would like to support this institution and hopefully, concerned families will profit from this kind of care.