Expand your knowledge!

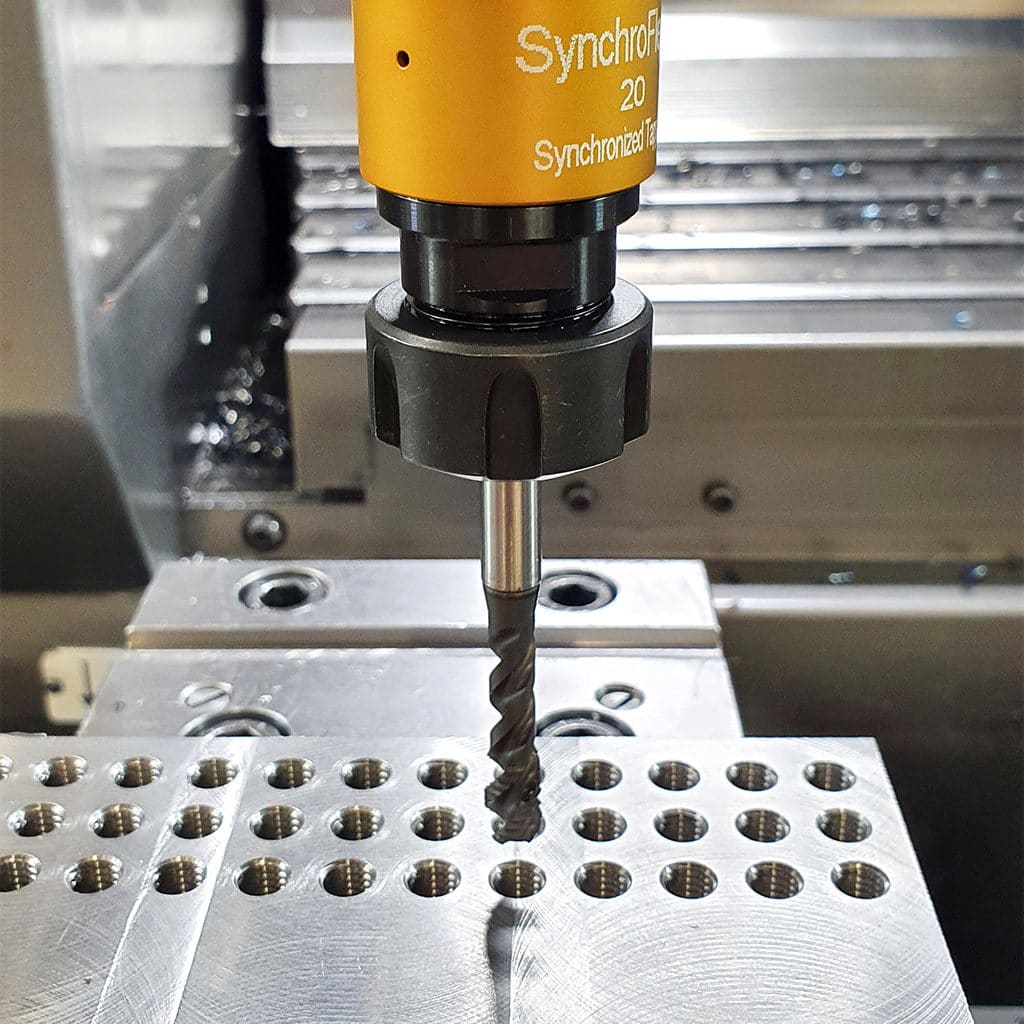

Tapping is presented as an easy process to master. However, choosing the wrong tap in relation to the material to be tapped can cause serious errors. It is important that this, usually the last, work step is implemented with a high level of process reliability – a tool breakage during tapping can destroy the entire previous value creation.

In order to meet the high demands of tapping, precision tools must be developed that can be used universally while realising more performance and longer tool life. We explain why PM taps with Hardlube coating are particularly well suited for this task.

Due to the good properties of high-performance steel (HSS), tools are mainly made of HSS for tapping. The alloying element cobalt is of particular importance here; this is added to HSS-E during production. PM HSS describes how the HSS was produced. A direct comparison shows that the tool life of a PM tap is considerably longer than that of an HSS-E tap.

In our white paper on “More performance in tapping“, we look at how you can manufacture threads economically and with process reliability. Learn among other things:

Are you also interested in the topics “Trochoidal milling: reducing costs, optimising processes“, “Producing deep-hole bores with process reliability“, and “Machine deburring“?

In these white papers we shed light on these disciplines and have summarised the most important information for you – for economic and efficient production.