Aluminium

Which end mill is best for machining aluminium?

Aluminium is the classic lightweight material and is generally considered to be easy to machine. Machining aluminium requires about a third of the cutting forces required to machine steel, which means less stress on the cutting tools. Aluminium’s good thermal conductivity also allows it to dissipate heat during machining – but this also carries the risk of chips sticking together and blocking the chip groove.

There are several parameters to consider when milling of aluminium safely and effectively. Using the right tools will help you achieve the best results. One key factor to consider is the tool coating. Read on for tips and tricks on machining aluminium.

Aluminium machining challenges

Despite its good machinability, there are specific challenges when milling aluminium:

- Chip formation and edge build-up: Aluminium tends to adhere to the cutting edge, resulting in built-up edges. This affects the surface finish achieved and can increase tool wear. In addition to selecting the right end mills, proper cooling can also help.

- Thermal development: Although aluminium dissipates heat well, if cooling is neglected, excessive heat can be generated, leading to dimensional deviations. An effective coolant management is therefore essential.

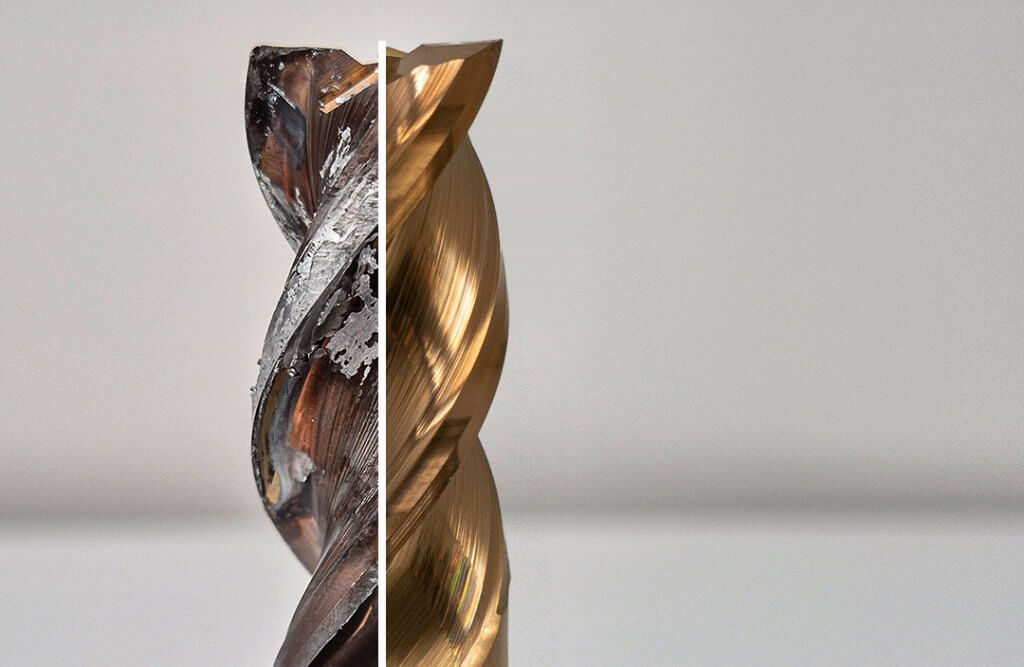

In CNC milling of aluminium, frictionless chip removal has a major impact on the machining result. This is achieved by the polished flutes on the end mills, which reduce the adhesion of sticky aluminium chips. Chip clearance can be further improved with a suitable coating.

Now, let’s look at why you should use application-specific tools rather than general purpose tools when machining aluminium.

Efficient machining of aluminium – our solution!

Because aluminium is very malleable and can even melt when heated, chips can stick together and block the flute, which can lead to tool breakage. These challenges can be overcome with special aluminium end mills. This is especially true if you frequently machine aluminium and other non-ferrous metals and value high productivity, good surface finish and process reliability.

Your tool for precise machining of non-ferrous metals

We have expanded our range of end mills for efficient machining of non-ferrous metals such as copper, brass or bronze, plastics and, in particular, aluminium, and aluminium alloys. We offer aluminium end mills in a variety of designs: sharp-edged, with corner radius, with and without internal coolant, with and without chip breaker, HA, or HB shank, with TiB2-based MnAlu coating or DLC coatings. These special coatings are chemically very inert to bonding with other materials, making the tools ideal for machining non-ferrous metals as cold welding is avoided.

The use of the new solid carbide end mills in the Aluminium Line offers several advantages:

- Polished cutting edges for clean surfaces

- Improved tool life up to 30% longer due to various coating options

- Optimised geometry for excellent chip formation and removal, high running smoothness and avoidance of vibration and chatter marks on the workpiec

- Suitable coatings: All new aluminium end mills have two coating options – MnAlu or DLC coating

- Wide range of dimensions

- The distinctive feature of the 4 to 6 tooth the end mills is the chip breaker on the cutting edge. This means that good surface finishes can be achieved even with long, multi-fluted end mills in non-ferrous metals. Shorter chips also make it easier to remove the chips from the machining area.

- The right solution for every application: Slot milling up to 2xD, pocket milling, ramping, helical milling, finishing and special designs for trochoidal milling

Introducing our new high-performance aluminium end mills

Z3 Standard length, sharp-edged and with corner radius

- MnAlu/MnDLC coating for reduced wear, especially in Al with high Si content (12%)

- Optimally shaped flutes for optimum removal of chips and reduced vibrations

- Unequal pitch and twist pitch for smooth running

- Polished cutting edges for maximum process reliability and surface quality

Z3 Long version, sharp-edged and with corner radius

- MnAlu/MnDLC coating for optimum service life and high resistance to wear

- Optimally shaped flutes for optimum removal of chips and reduced vibrations

- Unequal pitch and twist pitch for smooth running

- Polished cutting edges for maximum process reliability and surface quality

- Series 22308/ 22309 (DLC) with IC

Z4 with chip breaker

- MnAlu/MnDLC coating for optimum service life and high resistance to wear

- Chip breaker for good surface finishes

- Optimally shaped flutes for optimum removal of chips and reduced vibrations

- Unequal pitch and twist pitch for smooth running

- Polished cutting edges for maximum process reliability and surface quality

Z6 with chip breaker

- MnAlu/MnDLC coating for optimum service life and high resistance to wear

- Chip breaker for good surface finishes

- Optimally shaped flutes for optimum removal of chips and reduced vibrations

- Unequal pitch and twist pitch for smooth running

- Polished cutting edges for maximum process reliability and surface quality

- Available as standard length and long version

Okay, so what exactly do I gain from the new aluminium milling tools?

The use of specialised tools can significantly improve the efficiency and quality of aluminium machining. Your benefits are:

- Cost-effective production: Our aluminium specialists can be used at higher feed rates. This means higher material removal rates in less machining time.

- Reduced wear: The extremely smooth DLC coating reduces flank wear by up to 20%. Particularly suitable for high-silicon aluminium (12%); coefficient of friction <0.10; maximum operating temperature 500°C; coating thickness 0.3µm; hardness 6,500 HV.

- Maximum tool life: The MnAlu coating can extend tool life by up to 30%. Coefficient of friction approx. 0.45; maximum operating temperature 1,100°C; coating thickness 0.2µm; hardness 4,000 HV.

- Our commitment to quality: The geometry of our carbide end mills is optimised for aluminium machining, ensuring smooth operation, and eliminating vibration and chatter on the workpiece.

- Optimum functionality: Our new aluminium end mills achieve consistently good surface finishes (Ra <0.2µm, Rz <1.5µm) and exceptionally good chip formation and transport.

Here you can see the 22314 (Z6, chip breaker), 22310 (Z4, chip breaker) and 22304 (Z3) aluminium end mills machining AlCuMgPb F37 (3.1645).

Aluminium machining tips and tricks

Lightweight metal, but heavy work? No problem! We’ve got all the tips you need.

Which aluminium is best for machining? Aluminium is divided into three material classes:

- Aluminium with low tensile strength – often resulting in built-up edges.

- Aluminium with higher tensile strength and lower wear.

- The so-called free-cutting materials – short-breaking chips and low tendency to form built-up edges.

The machinability of aluminium depends largely on the specific alloy. In general, the higher the tensile strength of an aluminium alloy, the better it can be machined.

Pure aluminium and alloys with low tensile strength tend to form long chips and can cause the tool to stick, making machining more difficult. So-called free-cutting alloys, which are specially designed for machining, are particularly easy to machine.

It is important to bear in mind that the appropriate choice of aluminium alloy depends on the specific project requirements, such as mechanical properties, corrosion resistance and further processing such as welding or anodising.

The stability and sharpness of the end mill is crucial when machining aluminium. Polished cutting edges provide a smooth surface and improve chip evacuation, while large, smooth chip spaces also contribute to efficient evacuation of chips. Finally, it is important to find the best possible ratio between edge loading and chip evacuation.

The right combination of cutting speed and feed will give an optimum surface finish and prevent wear. Depending on the aluminium alloy, the recommended cutting speed is between 250 and 500 m/min and a feed rate between 0.02 and 0.30 mm/Z (tooth). The specific values depend on the cutting diameter and the machining task and can be found in our technical documentation.

The use of a suitable coolant helps to prevent the chips from sticking together. If the machining area becomes too hot, temperature variations can occur in the material, which can have a negative effect on tool life or dimensional accuracy, for example. Care must be taken to cool the material during machining.

The milling strategy has a direct effect on the quality of the workpiece. Therefore, it should be the focus of attention and be in line with your requirements!

Buy new vs. regrind

- Extend their performance well beyond the original tool life

- Maximise their profitability by reducing the cost of replacement

- Ensure consistent high quality in your manufacturing operations.

Aluminium – lightweight, popular, challenging

Aluminium is a lightweight non-ferrous metal with a density of approximately 2.7 g/cm³, making it a preferred material in applications where weight is a critical factor. It has good corrosion resistance, high thermal and electrical conductivity, and excellent formability.

Because of its versatility, aluminium is used in a wide range of industries:

- Automotive: Used in engine blocks, transmission housings and body parts to reduce weight and improve fuel efficiency.

- Aerospace: Used in aircraft structures and components due to its excellent strength-to-weight ratio.

- Construction: Used in facades, windows, and doors due to its corrosion resistance and light weight.

- Electronics: Used in enclosures and heat sinks due to its high thermal conductivity.

More information about aluminium? Of course! You can find out even more in episode 5 of our explainer videos, Span-Art ©.